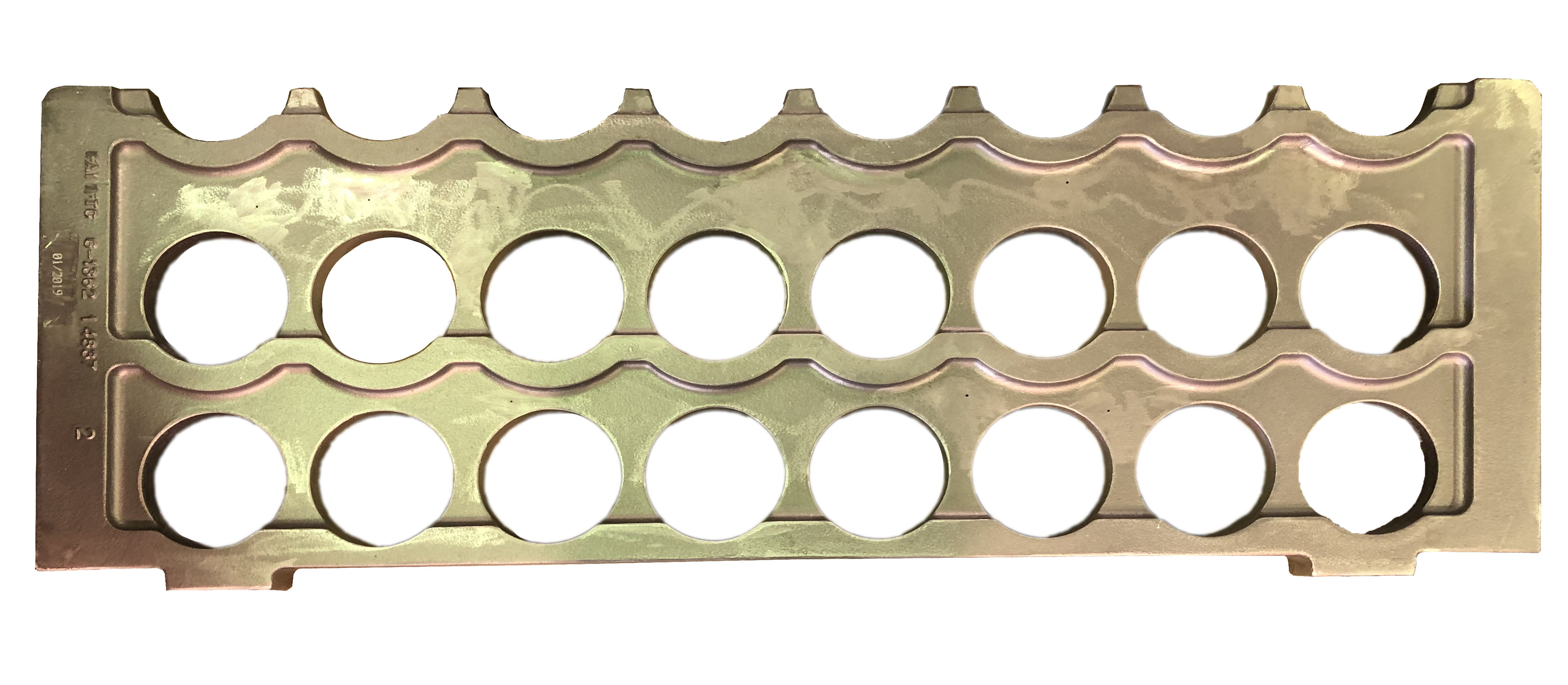

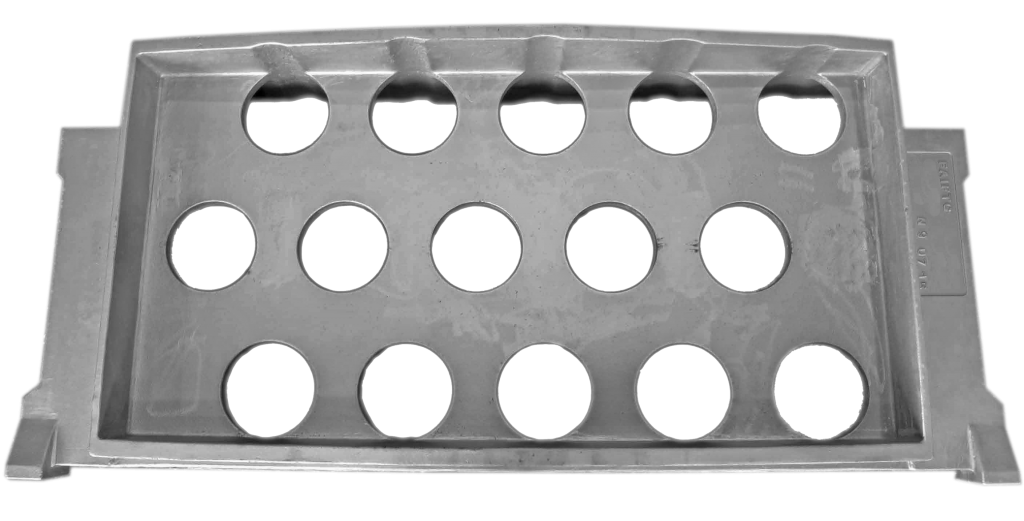

In convection zones of most process furnaces, tube sheets are used for tube bundle heat exchangers. In high temperature environments cast tube sheets are state of the art, as cast alloys are far superior to wrought materials in terms of creep strength at high temperatures.

The main reason for this is carbide formation, which is much more pronounced in cast materials due to the approximately twice as high carbon content. Cast tube sheets can sometimes be replaced by welded structures, but then often have to be made with twice the wall thickness. Nevertheless, welded constructions have their right to exist. We supply cast and welded tube sheets, as well as the associated brackets and guides. In addition, we support you in the design, development of a functional and castable design, in the selection of materials and in the necessary tests. FEM calculations and technical casting simulations enable us to create a load- and casting-compliant design. Of course, a complete production documentation is part of an order and is taken very seriously by us. In the event of damage, we are happy to help with an analysis, recalculate your load cases and optimise an existing design.