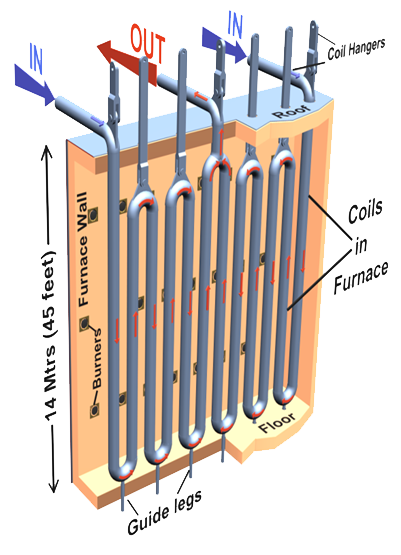

Coils for steam crackers contain straight or inductively bent centrifugally cast tubes and if necessary, cast fittings which are welded to form a unit. Individual pipe segments of 4-6 metres in length are bored and welded to a total length of 12-14 metres. The coils or smaller components are tested by us, delivered with all necessary certificates and finally welded/completed to a pressure vessel by the customer in the furnace. The components can be manufactured in all heat-resistant materials. Preferably, however, the micro-alloyed and proprietary materials of our Paralloy are used. The latest development generation is the aluminium-containing material Optim-AL, which, thanks to the formation of an inert aluminium oxide layer, offers exceptionally good protection against carburisation, less coking especially in gas crackers and a considerably longer service life overall. The requirements of the Pressure Equipment Directive or Health and Safety are met, as are extensive documentation of the required tests, certificates and individual expert opinions.